80GWP40-7-2.2不锈钢排污泵概述:

80GWP40-7-2.2不锈钢排污泵是上海速能以优质耐腐的不锈钢材质生产的一款在排放长纤维垃圾、固体颗粒垃圾和腐蚀性液体垃圾上具有独特功效的新一代泵类产品。因为它在普通管道排污泵的基础上又采用了不锈钢材质,所以GWP型不锈钢排污泵除了具有无堵塞、防缠绕、自动安装、自动控制、稳定性高等优势外,还有更加优秀的耐腐蚀性,使得它的使用寿命进一步延长,材质性能更稳定。

80GWP40-7-2.2不锈钢排污泵型号意义:

例如:80GWP40-7-2.2

80—进出口口径(mm)—(毫米)

GW—管道排污泵

40—额定流量(m3/h)—(立方/每小时)

7—扬程(m)—(米)

2.2—功率(KW)—(千瓦/时)

P—不锈钢材质

(小功率,中等口径不锈钢管道排污泵)

1、80GWP40-7-2.2不锈钢排污泵因其不锈钢的特殊材质,更加适用于带腐蚀性介质液体的排放,还可用于自来水厂给水、农田灌溉等清水的输送。

2、严重污染废水的排放、城市污水处理厂排水系统、医院、宾馆的污水排放、住宅区的污水排污站、矿山配套附机、人防系统排水站、农村沼气池、市政工程建筑工地等行业也广泛使用。

| GWP不锈钢管道排污泵型号 |

流量 (m3/h) |

扬程 (M) |

功率 (kw) |

口径 mm |

转速 (r/min) |

效率 (%) |

使用扬程范围(m) |

| 25GWP8-22-1.1 | 8 | 22 | 1.1 | 25 | 2900 | 45 | 10-22 |

| 32GWP12-15-1.1 | 12 | 15 | 1.1 | 32 | 2900 | 45 | 7-15 |

| 40GWP15-15-1.5 | 15 | 15 | 1.5 | 40 | 2900 | 48 | 6-15 |

| 40GWP15-30-2.2 | 15 | 30 | 2.2 | 40 | 2900 | 54 | 15-30 |

| 50GWP20-7-0.75 | 20 | 7 | 0.75 | 50 | 2900 | 51 | 3-7 |

| 50GWP10-10-0.75 | 10 | 10 | 0.75 | 50 | 2900 | 52 | 4-10 |

| 50GWP20-15-1.5 | 20 | 15 | 1.5 | 50 | 2900 | 53 | 6-15 |

| 50GWP15-25-2.2 | 15 | 25 | 2.2 | 50 | 2900 | 54 | 10-25 |

| 50GWP18-30-3 | 18 | 30 | 3 | 50 | 2900 | 55 | 15-30 |

| 50GWP40-15-4 | 40 | 15 | 4 | 50 | 2900 | 55 | 8-15 |

| 50GWP25-32-5.5 | 25 | 32 | 5.5 | 50 | 2900 | 55 | 17-32 |

| 50GWP20-40-7.5 | 50 | 20 | 7.5 | 50 | 2900 | 58 | 20-40 |

| 65GWP25-15-2.2 | 25 | 15 | 2.2 | 65 | 2900 | 50 | 6-15 |

| 65GWP37-13-3 | 37 | 13 | 3 | 65 | 2900 | 57 | 6-13 |

| 65GWP25-30-4 | 25 | 30 | 4 | 65 | 2900 | 61 | 15-30 |

| 65GWP30-40-7.5 | 30 | 40 | 7.5 | 65 | 2900 | 56 | 20-40 |

| 65GWP35-50-11 | 35 | 50 | 11 | 65 | 2900 | 45 | 35-50 |

| 65GWP35-60-15 | 35 | 60 | 15 | 65 | 2900 | 65 | 40-60 |

| 80GWP60-13-5.5 | 60 | 13 | 5.5 | 80 | 2900 | 67 | 7-13 |

| 80GWP40-7-2.2 | 40 | 7 | 2.2 | 80 | 1450 | 59 | 3-7 |

| 80GWP43-13-3 | 43 | 13 | 3 | 80 | 2900 | 70 | 5-13 |

| 80GWP40-15-4 | 40 | 15 | 4 | 80 | 2900 | 61 | 6-15 |

| 80GWP65-25-7.5 | 65 | 25 | 7.5 | 80 | 2900 | 63 | 12-25 |

| 100GWP80-10-4 | 100 | 10 | 4 | 100 | 1450 | 65 | 4-10 |

| 100GWP100-15-7.5 | 100 | 15 | 7.5 | 100 | 1450 | 68 | 8-15 |

| 100GWP110-10-5.5 | 110 | 10 | 5.5 | 100 | 1450 | 66 | 5-10 |

| 100GWP80-20-7.5 | 80 | 20 | 7.5 | 100 | 1450 | 65 | 10-20 |

| 100GWP100-25-11 | 100 | 25 | 11 | 100 | 1450 | 70 | 10-25 |

| 100GWP100-30-15 | 100 | 30 | 15 | 100 | 1450 | 65 | 12-30 |

| 100GWP100-35-18.5 | 100 | 35 | 18.5 | 100 | 1450 | 68 | 15-35 |

| 125GWP130-15-11 | 130 | 15 | 11 | 125 | 1450 | 72 | 7-15 |

| 125GWP130-20-15 | 130 | 20 | 15 | 125 | 1450 | 75 | 10-20 |

| 150GWP145-9-7.5 | 145 | 9 | 7.5 | 150 | 1450 | 76 | 4-9 |

| 150GWP180-15-15 | 180 | 15 | 15 | 150 | 1450 | 69 | 5-15 |

| 150GWP180-20-18.5 | 180 | 20 | 18.5 | 150 | 1450 | 72 | 8-20 |

| 150GWP180-25-22 | 180 | 25 | 22 | 150 | 1450 | 78 | 12-25 |

| 150GWP130-30-22 | 130 | 30 | 22 | 150 | 1450 | 78 | 15-30 |

| 150GWP180-30-30 | 180 | 30 | 30 | 150 | 1450 | 78 | 15-30 |

| 150GWP200-30-37 | 200 | 30 | 37 | 150 | 1450 | 73 | 13-30 |

| 200GWP300-7-11 | 300 | 7 | 11 | 200 | 980 | 66 | 3-7 |

| 200GWP250-11-15 | 250 | 11 | 15 | 200 | 1450 | 64 | 4-11 |

| 200GWP250-15-18.5 | 250 | 15 | 18.5 | 200 | 1450 | 73 | 7-15 |

| 200GWP400-10-22 | 400 | 10 | 22 | 200 | 1450 | 75 | 5-10 |

| 200GWP400-13-30 | 400 | 13 | 30 | 200 | 1450 | 76 | 6-13 |

| 200GWP300-15-22 | 300 | 15 | 22 | 200 | 1450 | 76 | 8-15 |

| 200GWP250-22-30 | 250 | 22 | 30 | 200 | 1450 | 71 | 12-22 |

| 200GWP350-25-37 | 350 | 25 | 37 | 200 | 1450 | 71 | 10-25 |

| 200GWP400-30-45 | 400 | 30 | 45 | 200 | 1450 | 74 | 13-30 |

| 250GWP600-9-30 | 600 | 9 | 30 | 250 | 980 | 78 | 3-9 |

| 250GWP600-12-37 | 600 | 12 | 37 | 250 | 1450 | 76 | 5-12 |

| 250GWP600-15-45 | 600 | 15 | 45 | 250 | 1450 | 73 | 6-15 |

| 250GWP600-20-55 | 600 | 20 | 55 | 250 | 1450 | 73 | 8-20 |

| 250GWP600-25-75 | 600 | 25 | 75 | 250 | 1450 | 71 | 12-25 |

| 300GWP800-12-45 | 800 | 12 | 45 | 300 | 980 | 74 | 5-12 |

| 300GWP480-15-45 | 480 | 15 | 45 | 300 | 1450 | 66 | 7-15 |

| 300GWP800-15-55 | 800 | 15 | 55 | 300 | 1450 | 73 | 8-15 |

| 300GWP600-20-55 | 600 | 20 | 55 | 300 | 1450 | 73 | 10-20 |

| 300GWP800-20-75 | 800 | 20 | 75 | 300 | 1450 | 75 | 11-20 |

| 300GWP950-20-90 | 950 | 20 | 90 | 300 | 1450 | 76 | 11-20 |

| 300GWP1000-25-110 | 1000 | 25 | 110 | 300 | 1450 | 76 | 12-25 |

| 300GWP1100-10-55 | 1100 | 10 | 55 | 300 | 1450 | 73 | 4-10 |

| 350GWP1500-15-90 | 1500 | 15 | 90 | 350 | 740 | 87 | 6-15 |

| 350GWP1200-18-90 | 1200 | 18 | 90 | 350 | 980 | 85 | 8-18 |

| 350GWP1100-28-132 | 1100 | 28 | 132 | 350 | 980 | 84 | 15-28 |

| 350GWP1000-36-160 | 1000 | 36 | 160 | 350 | 980 | 84 | 20-36 |

| 400GWP1760-7.5-55 | 1760 | 7.5 | 55 | 400 | 980 | 83 | 4-7.5 |

| 400GWP1500-10-75 | 1500 | 10 | 75 | 400 | 980 | 86 | 3-10 |

| 400GWP2000-13-110 | 2000 | 13 | 110 | 400 | 980 | 84 | 7-13 |

| 400GWP2000-15-132 | 2000 | 15 | 132 | 400 | 980 | 83 | 6-15 |

| 400GWP1700-22-160 | 1700 | 22 | 160 | 400 | 980 | 83 | 10-22 |

| 400GWP1500-26-160 | 1500 | 26 | 160 | 400 | 980 | 84 | 12-26 |

| 400GWP1800-32-250 | 1800 | 32 | 250 | 400 | 980 | 82 | 17-32 |

| 400GWP1700-30-200 | 1700 | 30 | 200 | 400 | 980 | 82 | 15-30 |

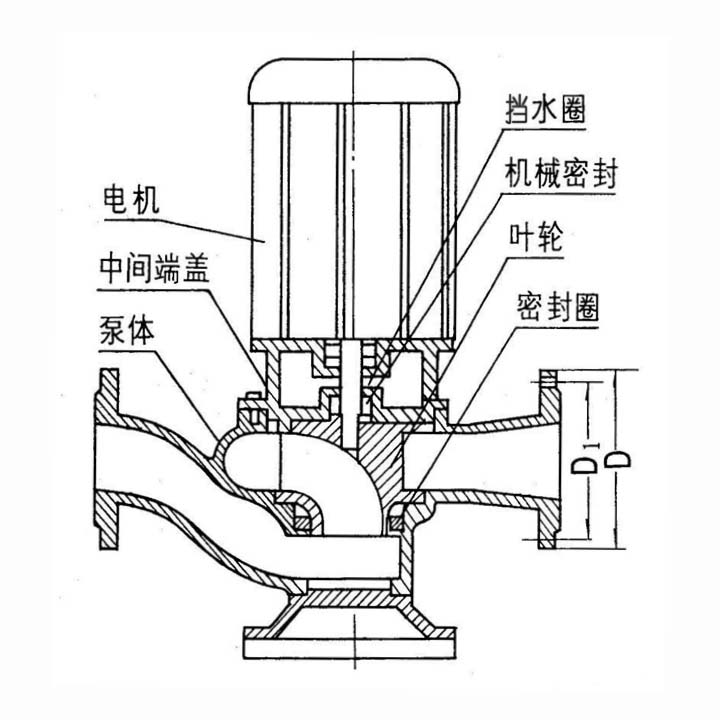

1、80GWP40-7-2.2不锈钢排污泵与电机同轴直连,实现了机电一体化,结构紧凑,体积小,可节省基建费用。电机风叶端加上防护罩,可置于户外工作。因其不锈钢材质,有良好的耐腐蚀性,配套电机设计合理,降低噪音,提高效率,节能效果显著,实现泵运行的综合稳定。

2、GWP排污泵采用立式结构,进出口的法兰规格是一样的,且进出口的中心线在同一水平线上,使得泵的安装和拆卸很容易进行。该泵可以连续安全运行8000小时以上,因为它的机械密封融合了硬质耐磨碳化钨耐用、耐磨的特性。大流道抗堵塞水力部件设计,使直径为泵口径约50%的固体颗粒和泵口径的5倍纤维物质都可以顺利排出,大大提高了污物通过能力。